Basics of AWS Filler Metal and Electrode Classification

Achieving quality results in any welding operation is a matter of having the right equipment and filler metal, as well as the appropriate level of welding operator skill to complete the job efficiently and accurately. Productivity and cost savings matter in an industry where competition can be tight.

In addition to the right welding technique, it is also beneficial for welding operators to have a solid understanding of the welding procedures required for the application and know the classifications of filler metals being used.

American Welding Society (AWS) classifications for filler metals provide valuable information about their usability, including what materials they are best suited for and how to use these products in a way that maximizes performance. They also offer insight into the mechanical properties that a given filler metal will provide.

In other words, AWS classifications set the standard for filler metals, so there is a general understanding or awareness of what results a specific stick electrode or wire will produce. Those standards are then used by filler metal manufacturers for their product formulations and drive greater consistency across different manufacturers from a welding, chemistry and mechanical property standpoint. Should a primary filler metal supplier run out of a given filler metal or there is an issue acquiring it, a secondary manufacturer will likely offer a product with the same AWS classification to provide the same chemical and mechanical properties — even if the filler metal has nuanced differences during the welding process. For example, the wetting action or arc starting may be different between similarly classified products from different manufacturers, but the general usability and capabilities are the same.

Knowing AWS classifications assists welding operators when they aren’t familiar with a product and don’t necessarily know what it will do by trade name. Armed with this information, they can look at the classification and understand its properties — how to operate it and whether it delivers low diffusible hydrogen, for instance.

The most important information provided by AWS classifications are designators that indicate:

1) Whether the product is a stick electrode, solid wire or tubular wire

2) The position in which it should be used

3) Its strength classifications

4) Its chemistry/composition

Examples of these critical classifications are outlined below, alongside their respective charts, for three common AWS specifications for carbon steel filler metals. These charts and explanations help demonstrate the key differences between classifications, and provide insight into other optional designators, which can be equally important to understand.

Keep in mind that AWS classifications vary in their nomenclature between stick electrodes, solid wires and flux-cored wires discussed here. However, products within the following specification examples — AWS A5.1 (Carbon Steel Electrodes for Shielded Metal Arc Welding), A5.18 (Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding) and A5.20 (Carbon Steel Electrodes for Flux Cored Arc Welding) — are all filler metals usable for a variety of mild steel applications. These include general fabrication, rail car fabrication, shipbuilding, heavy equipment manufacturing and more.

A5.1 (Carbon Steel Electrodes for Shielded Metal Arc Welding)

This AWS specification provides the standards for, among other filler metals, a common classification of stick electrode: E7018.

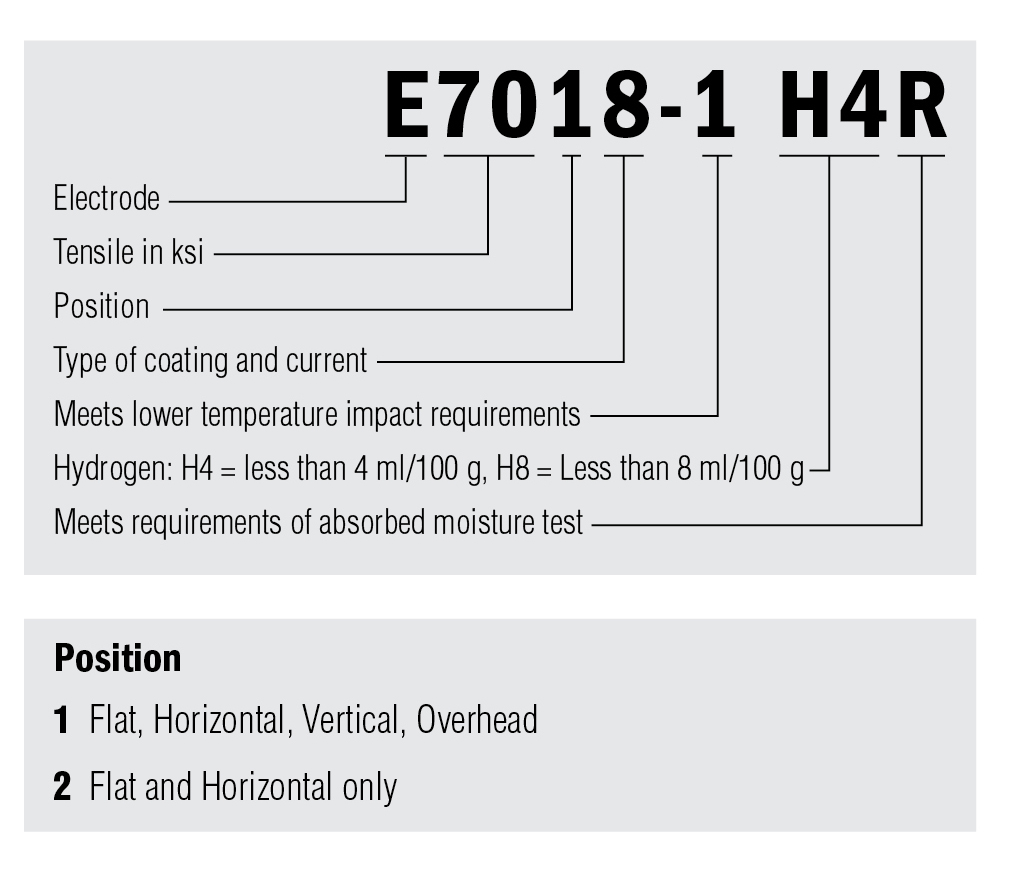

Like other stick electrodes, E7018 products have four key designators in their classification. See Figure 1.

A welding electrode is defined by AWS A3.0 Standard Welding Terms and Definitions “as a component of welding circuit through which current is conducted and that terminates at the arc, molten conductive slag, or base metal.”

E indicates the filler metal is an electrode, 70 provides the tensile strength in ksi, 1 shows the welding position, which in this case is all-position and 8 indicates the coating on the product.

Stick electrodes can also feature optional designators, as in the above example.

– 1 – Designates that the electrode meets the requirements for improved toughness and ductility

– H – Designates that the electrode meets the requirements of diffusible hydrogen testing

– R – Designates that the electrode meets requirements of absorbed moisture test/ optional supplement for low hydrogen electrodes

Some stick electrodes also feature an M, which designates that the electrode is intended to meet most military requirements.

A5.18 (Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding)”

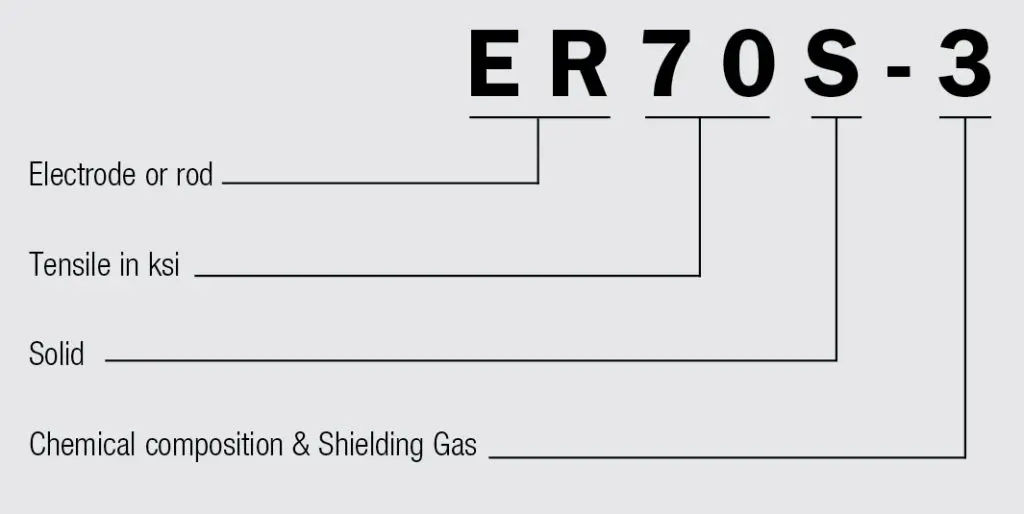

AWS ER70S-3 solid wire is a common filler metal within the A5.18 specification. As with the stick electrode example above, solid wires have a designator beginning with E (Electrode), but are also accompanied by an R (Rod). Welding rod in AWS A3.0 Standard Welding Terms and Definitions is defined “as a form of welding filler metal, normally packaged in straight lengths, that does not conduct the welding current.”

This means that the product can be used in the Electrod form or Rod form (typically cut lengths of solid rod for the GTAW process). The S later in the classification designates that this is a solid wire product. See Figure 2 for an explanation of the other items indicated in an AWS classification for solid wire, including chemical composition.

Solid wires can also feature an optional designator of H, which, like a stick electrode indicates that the electrode or rod meets requirements of diffusible hydrogen.

A5.20 (Carbon Steel Electrodes for Flux-Cored Arc Welding)

Lastly, as an example of an AWS classification for a gas-shielded flux-cored wire, consider an E70T-1X product in Figure 3 below. This classification illustrates the use of additional designators, such as the C/M, which indicates that the wire can be used with either 100 percent CO2 or mixed gas of CO2 and argon. Again, the H represents the diffusible hydrogen levels.

The optional designator of J here shows that the electrode meets the requirements for improved toughness and will deposit weld metal with CVN properties of at least 20ft.lbs at -40 Fahrenheit.

There are also D or Q designators that can appear in AWS classifications for flux-cored wires. These show that the weld metal will meet supplemental mechanical property requirements with welding done using low heat input, fast cooling rate procedures and using high heat input, slow cooling rate procedures.

Regardless of the filler metal being used for the job — stick electrode, solid wire or flux-cored wire — understanding AWS classifications can help welding operators know the performance that they will gain from a given product and the way it is best used. As with any part of the welding operation, greater knowledge can lead to greater welding performance.

Related Articles:

Misconceptions about Welding Wire Strength

What Are Stickout, Electrode Extension and Contact-Tip-To-Work Distance?

thank you

very good