Aluminum Welding Guide

Welding Procedures – Shielding Gases Used For MIG And TIG Welding

Tungsten electrodes as specified in AWS A5.12

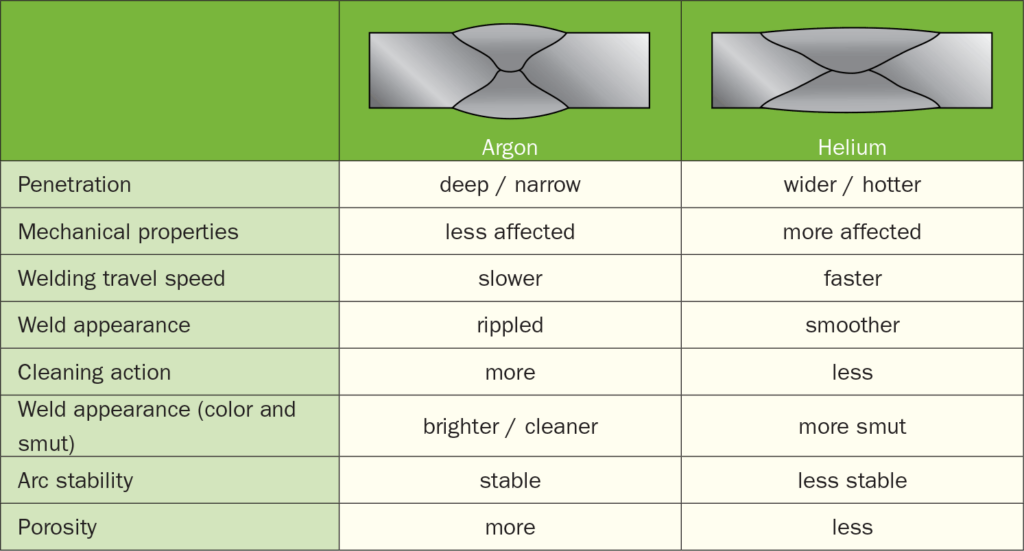

| MIG | 100% Argon – most commonly used 75% Helium & 25% Argon – Mixture used when deeper root penetration and reduced porosity are desired. |

| TIG | 100% Argon – most commonly used 25% Helium & 75% Argon – Mixture used when deeper root penetration and reduced porosity are desired. |

| Warning | Helium content greater than 25% may cause arc instability, when TIG welding. |

Pure argon is the most commonly used shielding gas. It is economical, has good arc cleaning properties, and produces a clean weld. Argon is heavier than air and gives excellent shielding gas coverage in the flat position. The addition of helium increases the ionization potential and the thermal conductivity of the shielding gas which produces greater heat conducted to the base metal through the arc. This feature causes an increase in weld penetration, an increased width of the weld root, and reduced porosity in the weld bead. The negatives of argon-helium gas mixtures are higher required flow rates because of the lower density of the gas and increased cost. Helium also increases weld discoloration because more magnesium is burned in the arc at the higher arc temperatures. The argon gas shall have a minimum purity of 99.997% and a dew point of -76 degrees F or lower. Helium shall have a purity of 99.995 % and a dew point of -71 degrees F or lower.