MAKING HARD WORK EASIER

FabCO® Triple 7 Gas-Shielded Flux Cored Wire

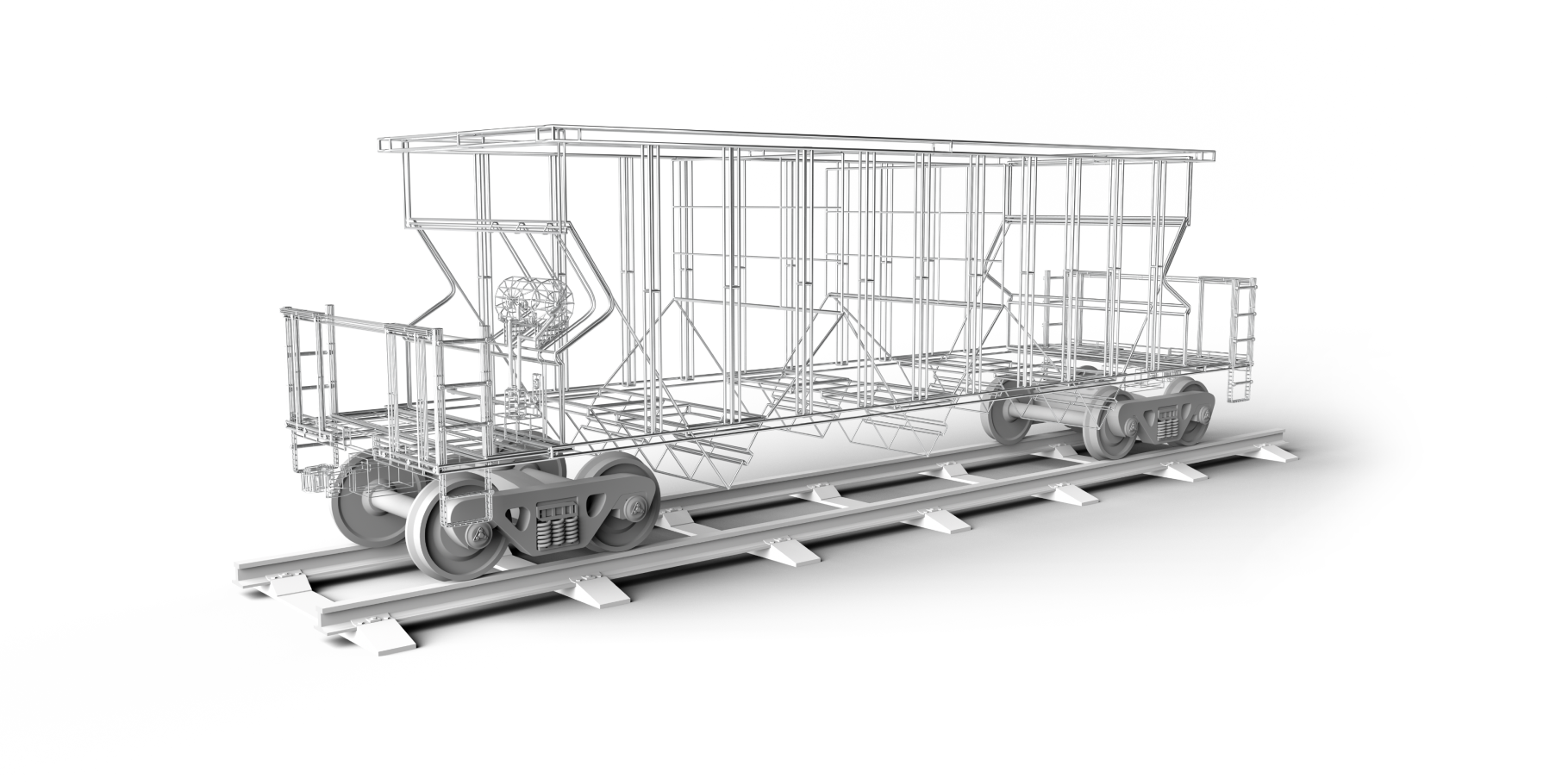

FabCO® Triple 7 gas-shielded flux-cored wire helps you expand what’s possible. With a more forgiving arc for a wider window of operation, it helps welders of any skill level lay down expert welds, and its expanded mechanical properties mean it can be used in both T-1 and T-9 applications. And it’s still made using steel melted and made in the USA.

EXPAND WHAT’S POSSIBLE

Triple 7: A Forgiving Arc For The Jobs That Aren’t

Get detailed specs, certifications, and packaging information on Triple 7 so you can get your team up and running with increased productivity and reduced costs.

Tried And True Down To The Core

GREATER VERSATILITY

The new, enhanced Triple 7 expands the types of jobs you can weld with it, so you can simplify your wire inventory.

AWS Classifications: E71T-1 C/M H8 and E71T-9 C/M H8 AWS.

ABS Approval: Toughness requirements of 3Y classification (mixed gases and 100% CO2).

AWS Approval: D1.8 Demand Critical Seismic Applications.

CWB Approval: 100% CO2 to 85% argon/15% CO2.

AWS Classifications: E71T-1 C/M H8 and E71T-9 C/M H8 AWS.

ABS Approval: Toughness requirements of 3Y classification (mixed gases and 100% CO2).

AWS Approval: D1.8 Demand Critical Seismic Applications.

CWB Approval: 100% CO2 to 85% argon/15% CO2.

CONSISTENT RESULTS

Expand your expectations of the quality that flux-cored wire should deliver. Triple 7 consistently produces great results.

Multiple shielding gases: Triple 7 excels throughout a range of amperages and is optimized using argon/CO2 mixes, but also runs great on 100% CO2.

Fast-freezing slag: Excellent weld pool control for consistent out-of-position welds.

Smooth, stable, spray-like arc: Creates a flat bead profile, so it’s easy to make great welds.

Multiple shielding gases: Triple 7 excels throughout a range of amperages and is optimized using argon/CO2 mixes, but also runs great on 100% CO2.

Fast-freezing slag: Excellent weld pool control for consistent out-of-position welds.

Smooth, stable, spray-like arc: Creates a flat bead profile, so it’s easy to make great welds.

IMPROVED PRODUCTIVITY, COST SAVINGS

Triple 7 has more forgiving arc characteristics in larger operating windows which boosts throughput and reduces expenses.

Easy-to-remove slag: Simplifes interpass and post-weld cleanup and reduces rework caused by slag inclusions.

Less risk of hydrogen cracking for less rework: The H8 designation ensures a weld deposit with less than 8ml of hydrogen per 100g of weldment.

Low spatter levels: Less cleanup time means more welding time.

Easy-to-remove slag: Simplifes interpass and post-weld cleanup and reduces rework caused by slag inclusions.

Less risk of hydrogen cracking for less rework: The H8 designation ensures a weld deposit with less than 8ml of hydrogen per 100g of weldment.

Low spatter levels: Less cleanup time means more welding time.

Get The Details On Triple 7

Find a distributor near you, or talk to one of our welding experts to understand how Triple 7 can maximize productivity for your welding application.